In form for the total system

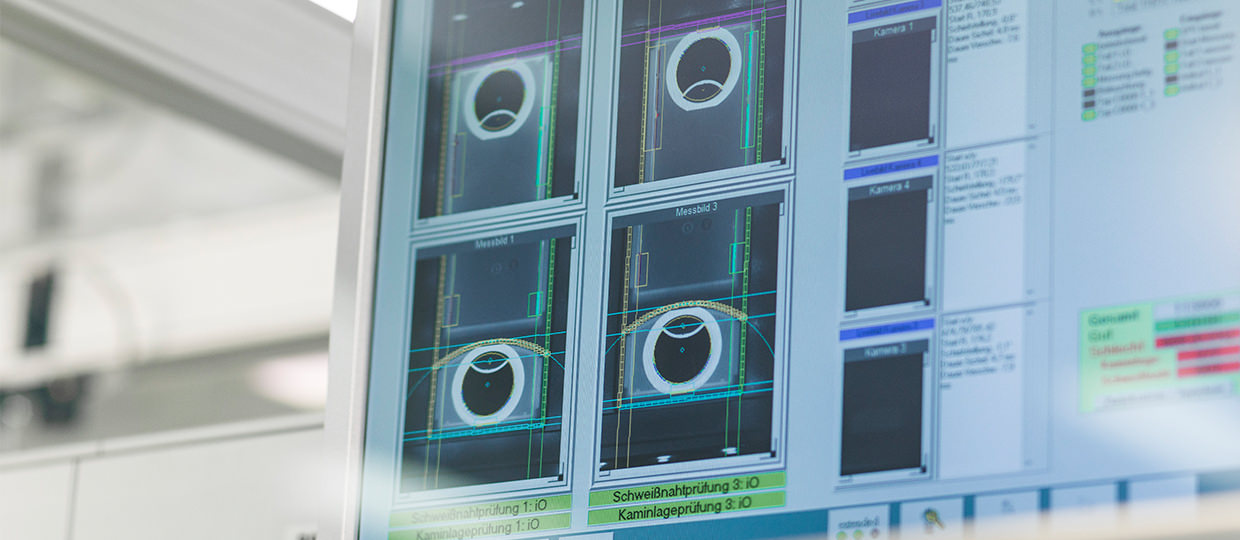

with fully automated joining procedures, 100 % camera tests and our comprehensive expertise as a full service supplier.

Interlinked, fully automated component assembly and test procedures.

As a full service supplier we assemble individual plastic components to complex assemblies and systems in a process-reliable way. Depending on the customer budget and requirement, we develop non-interacting, partly interlinked or fully interlinked assembly processes, using high-performance handling systems and state-of-the-art conveyor systems. Your quality requirements are ensured by integrated and individual test measures.

- Component assembly on all levels of automation

- Robot-based clean room assembly

- 1K and 2K sealant applications

- Fully automatic unbalance adjustment

- Quality control with 100 % camera test

Joining technology

With a wide range of interlinked joining technologies our experts take charge of a secure assembly of your components and downstream test procedures including all required inspection measures.

- Laser welding

- Ultra-sound welding

- Hot plate welding

- Vibration welding

- Bonding applications

- Further joining technologies, such as insert molding, pressure grouting, clamping and screwing

- Automated or manual assembly of complete components of different plastic parts

Testing procedure

As little as possible, as much as necessary. Our simultaneous and downstream quality inspections ensure your individual standards and the reproducibility of your plastic components in all test intensities required – from tactile up to optical measuring.

- Last filler point control through sensor or visional systems

- Leak tests

- Automatic unbalance measurement and weight control

- 100 % Camera tests

- Weld line detection by thermo-cameras

Packaging

By means of fully or partly automatic handling systems we meet your industrial specifications for packaging in terms of hygiene, protection against forgery and individualization.

- Clean room packaging in an inert gas atmosphere

- Inline labeling (Barcode, Data Matrix, UDI, inline DMC labeling)

- Individual labeling and identification

- Standardized and customer-specific packaging

Sealants

By applying 1K and 2K PUR foams we seal assemblies or components in line with the specifications – quickly and with high output quantities. Sealing beads are checked on defects and particle confinements by means of state-of-the-art camera technology.